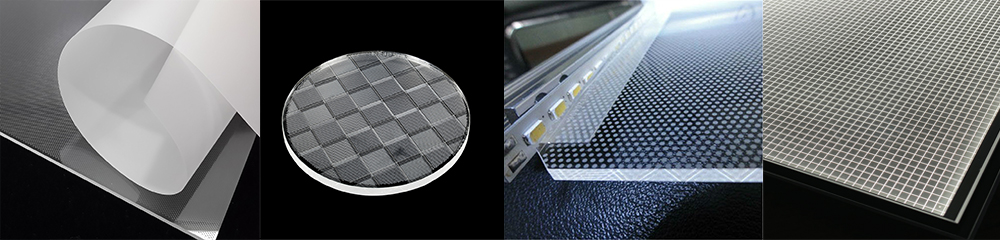

The light guide plate (LGP) uses an optical grade acrylic/PC sheet, and then uses high-tech materials with a very high refractive index and does not absorb light. The bottom surface of the optical grade acrylic sheet is engraved with laser dotted, V-cutting cross grid or UV screen printing technology prints light guide dots.

The optical grade PMMA acrylic sheet from Mitsubishi is used to absorb the light emitted from the lamp and stays on the surface of the optical grade acrylic sheet. When the light hits each light guide point, the reflected light will spread to all angles, and then destroy the reflection condition and shoot out from the front of the light guide plate.

The light guide plate (LGP)can emit light evenly through a variety of dense and different light guide points. The purpose of the reflective sheet is to reflect the light exposure on the bottom surface back into the light guide plate to improve the use efficiency of light。

In the case of the same area of luminous brightness, the luminous efficiency is higher and the power consumption is lower. The single-sided microstructure array light guide plate generally adopts an extrusion molding manufacturing process.

1. Principle introduction

The design principle of the light guide plate (LGP) is derived from the LCD screen of a laptop computer, and it is a high-tech product that transforms a line light source into a surface light source. Optical grade acrylic (PMMA)/PC as the base material, using LCD display and laptop backlight module technology, through the high light conductivity of the light guide point, the computer calculates the light guide point, so that the light of the light guide plate is refracted into The surface light source is manufactured in a uniform light state.

The products are manufactured under constant temperature, humidity, and dust-free environmental conditions. It has the distinctive characteristics of the ultra-thin, ultra-bright, uniform light guide, energy saving, environmental protection, no dark area, durability, not easy to yellow, simple and fast installation and maintenance.

2. Classification

2.1. Classified by shape.

Flat plate: The light guide plate is rectangular when viewed from the point of light incident.

Wedge-shaped plate: Also known as a sloping plate, from the point of light incident, one side is thick and the other is thin into a wedge (triangular) shape.

2.2. Classified by outlet

Printing: After the light guide plate finishes the shape processing, the dots are printed on the reflective surface by printing, which is divided into IR and UV.

Non-printing type: The dots are directly formed on the reflective surface when the light guide plate is formed. It is divided into chemical etching (Etching), precision mechanical characterization (V-cut), Laser dotted.

2.3. Classified by light direction

Side light type: Place the luminous body (tube or LED) on the side of the light guide plate.

Direct type: Place the luminous body (tube or LED) under the light guide plate.

2.4. Classified by Press forming

Injection molding: Use an injection molding machine to inject optical grade PMMA particles into a mold at high temperature and high pressure to cool and shape.

Cutting and forming: the optical grade PMMA original board is cut to complete the finished product.

3. Our Laser dotted Light guide plate (LGP)advantages

— High Uniformity over 90% , high light transmittance over 90% and High light conversion rate;

— Long lifespan can be used normally indoors for more than 8 years, safe and environmentally friendly, durable and reliable, will not get yellow, Applicable both indoors and outdoors;

— Our Laser dotted light guide plate (LGP) can be used normally indoors for more than 8 years, safe and environmentally friendly, durable and reliable, applicable both indoors and outdoors;

— Under the same brightness, thinner products can be used to save costs;

— Different dot patterns can be made by laser dotting according to customer requirements.